HS.600

+31 (0)36-534 80 20

info@avc.nl

Digital display

All AVC L-sealers may be easily operated via a transparent digital display. This is where the correct settings may be entered, checked and/or altered. Due to the digital display, there is minimal changeover time from one product to another.

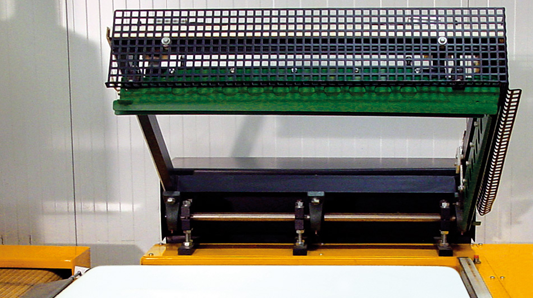

Option: Conveyor system

With the automatic conveyor system, your product automatically leaves the machine after the sealing window opens. The product may now be transported to a Shrink Tunnel or a conveyor belt, for example. Both the height and time of the automatic conveyor system are freely adjustable.

Option: Film winding unit

The excess film material is automatically transported to a reel. This minimises the number of work interruptions.

Option: Twin sealing system (TW)

In addition to the cut seam produced by the round wire, the twin sealing system provides your packaging with an extra sturdy flat seal (by means of two flat wires). Open packaging or holes in the shrink film are a thing of the past with this system. If required, the flat wires may be turned off with a switch.

Option: Electrical control (EM)

Instead of manual control, this option allows you to close the sealing window by means of electrical operation. You can close the window with a foot pedal or push button, leaving both your hands free to continue with the next package.

Option: Continuously heated sealing system (CVS)

Instead of sealing wires, this machine is equipped with a continuously heated sealing system. Sealing time is adjustable from 0.1-1.0 sec. Because the seal bar is kept at a constant temperature, a high production capacity may be achieved. This machine comes with an automatic conveyor system (see fig. 10) and pneumatic operation of the sealing window by means of a 2-button control.