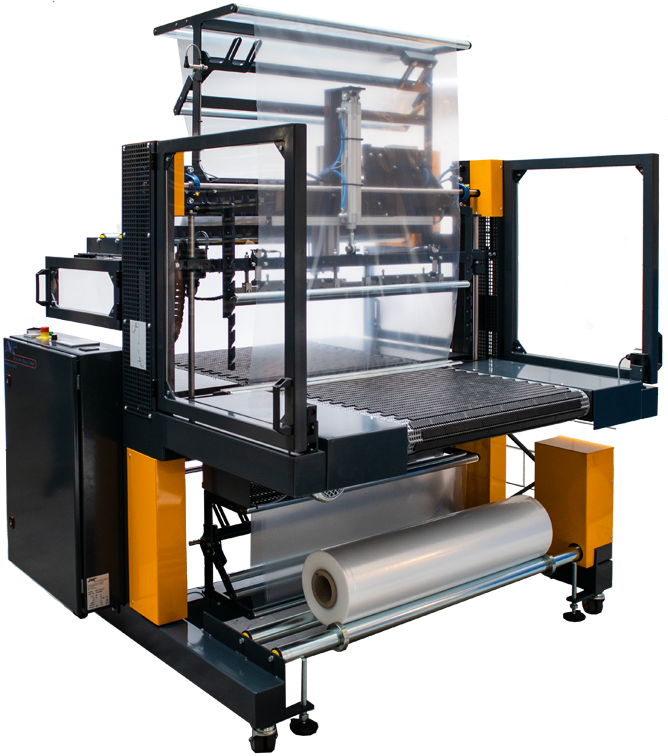

BP.900

+31 (0)36-534 80 20

info@avc.nl

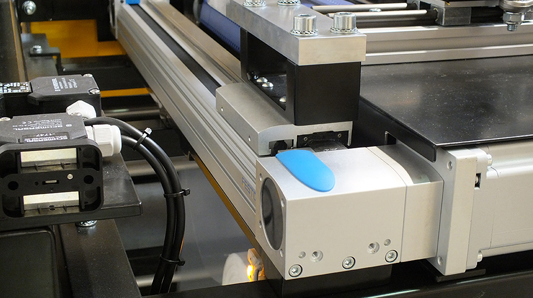

Touchscreen

The transparent touchscreen ensures simple operation in various languages. Besides the temperature, conveyor belt speed, processing time and sealing time may be set with great precision.

Twin sealing system (TW)

In addition to the cut seam produced by the round wire, the twin sealing system adds an extra sturdy flat seal (by means of two flat wires).

Option: Continuously heated sealing system (CVS)

Because we use a continuously heated sealing system in this machine, sealing time is exceptionally short: so the speed is higher. In addition, less maintenance will be required, while these Sleeve Wrappers are low maintenance anyway.

Film roll holder

The unrolling system is motor-driven in order to ensure consistent film feed.

Option: In-feed and out-feed belt

The driven in-feed and out-feed belt ensures easy transportation of the products through the Sleeve Wrapper, and on to the tunnel. This option is particularly recommended if several products or heavy products are processed.

Trayless packaging

A pusher unit facilitates packaging of products without a cardboard tray. The digital display allows for easy adjusting of the number of product rows.

Option: Servo section

Servo technology allows you to achieve a higher speed.

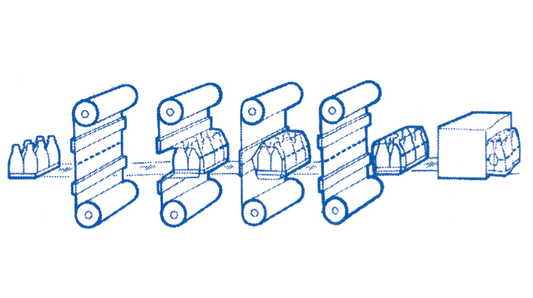

Drawing - explanation B

The product to be packaged automatically rolls against a curtain of shrink film. The sealing bar closes as soon as the products have passed through the film and the film has been cut. This essentially creates a loose film wrapped around the bundle. The whole unit then passes through the shrink tunnel where it is neatly sealed and shrunk before exiting the packaging line at the other end.